Perforated Sheet Metal.

Star Metal offers customised CNC turret punched perforated sheet metal for industrial, commercial & residential projects in WA.

WA OWNED & OPERATED

20 YEARS EXPERIENCE

SUPPLY & INSTALLATION

EXTENSIVE RANGE

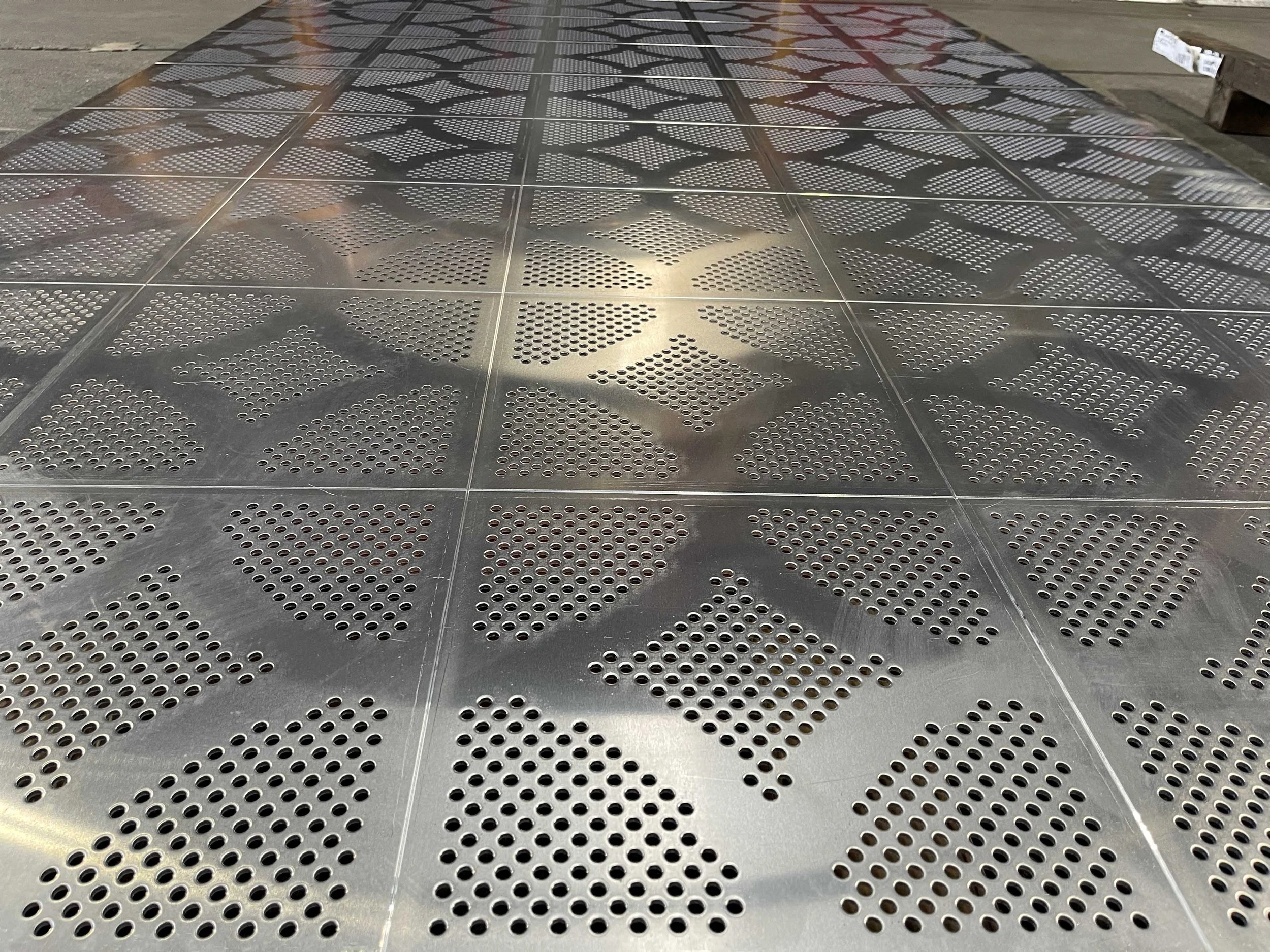

At Star Metal, we specialise in the fabrication of high-quality perforated sheet metal solutions for all industries. We offer a wide selection of perforation patterns, from geometric and abstract to nature-inspired and custom photo image designs. Whether your needs are for safety screening, privacy, solar screening, air ventilation, or to add design flair, there is a wide range of options. All of our perforated sheet is manufactured from the highest quality materials.

Our ability to provide a standardised pattern to a particular size or within a border makes our manufacturing process a better option than adapting off-the-shelf sheets with perforations punched to the sheet edges.

Choose from materials including:

✔ Aluminium – Lightweight, rust-resistant, and ideal for architectural facades.

✔ Stainless Steel – Durable, corrosion-resistant, and perfect for industrial applications.

✔ Mild Steel & Corten Steel – Aged finishes for unique architectural statements.

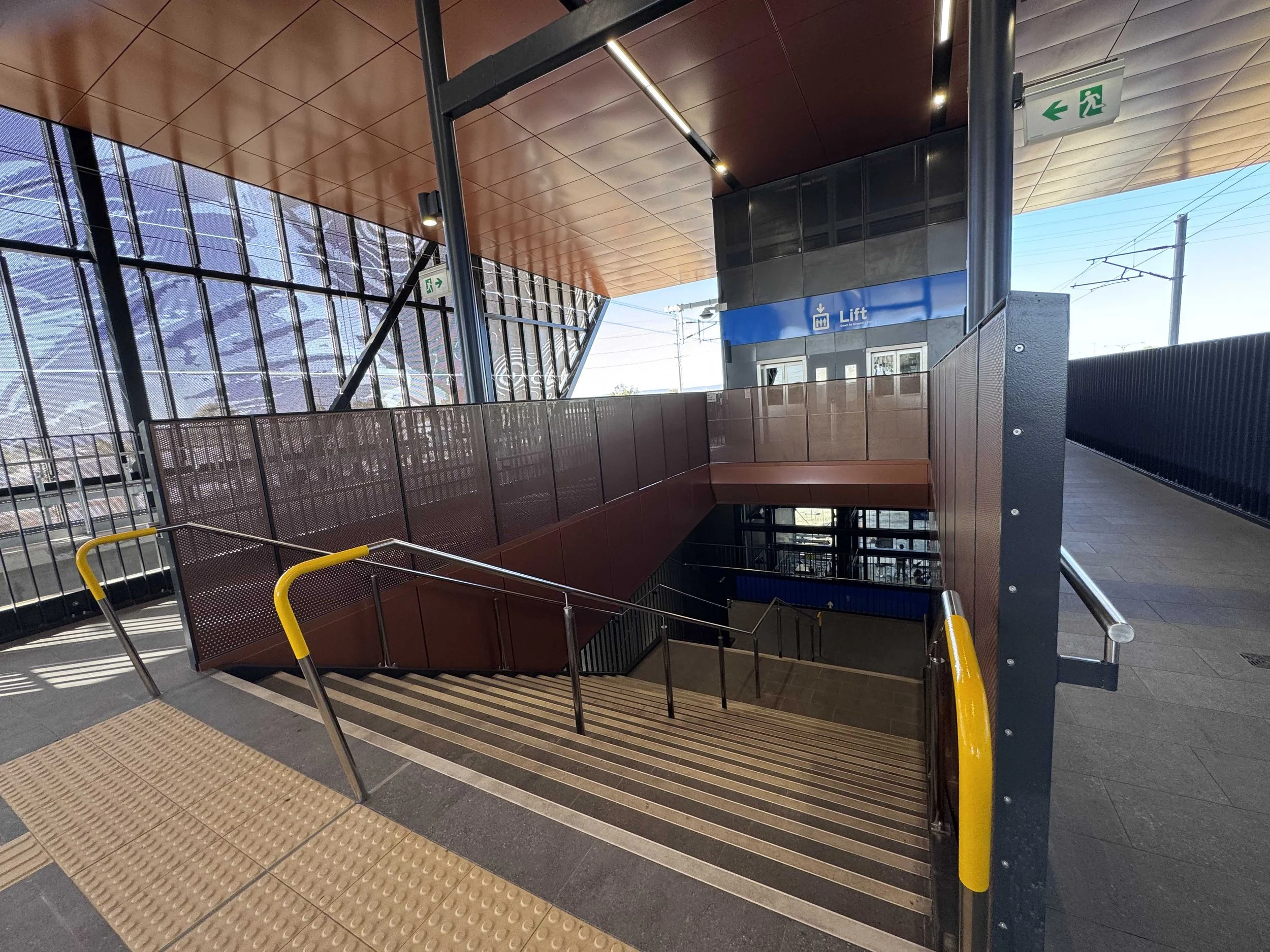

Perforated Sheet Metal for Architectural Balustrading.

Modern, versatile, and compliant perforated sheet metal is a smart choice for architectural balustrading. Customisable perforation patterns allow for creative expression, light filtering, and privacy control, making it ideal for both internal and external applications. With options in aluminium or stainless steel and a range of powder-coated finishes, perforated balustrades offer durability, low maintenance, and a sleek architectural finish that complements contemporary design.

Perforation Pattern Library

Our perforation patterns are used across a widerange of industries. Whether the application is for a large industrial project, commercial building facade or a residential balustrade or privacy screen project, there is bound to be a pattern perfect for your needs.

We’re ready to make something FAB

You design and we fabricate, helping in design where needed, using our experience in sheet metal fabrication.